Welding is a process where there are a huge number of hazards and safety procedures to follow to ensure you stay safe when welding. It’s essential to familiarize yourself with all the best practices and equipment to ensure the highest level of safety for you and anyone else in the welding environment.

This article will lead you through a basics of welding safety from what clothing is best to wear, to how to make sure you have a safe welding environment.

Whether you’re just welding alone in your garage, or if you run a welding workshop business, it’s absolutely vital that you read through all the safety manuals of all the equipment you purchase before using it. The same goes for anyone else who may be operating this equipment

Contents

Welding Protective Clothing

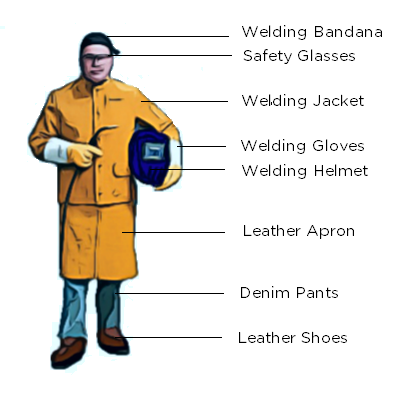

Arc welding produces sparks and emits rays which can cause damage to your skin and eyes if there aren’t protected properly. If you leave any skin exposed, it’s could easily result in burns. Below are some guidelines for what clothing to wear when welding.

The Well Dressed Welder

Below is an image of a welder with safety equipment.

Welding Gloves and Gauntlets

Always wear proper heat resistant welding gloves when welding. Modern welding gloves have come a long way since the “one size fits all“ days, and there are now different gloves available for specific processes. You can also buy them in a range of different materials, such as pig skin, deer skin, goat skin and kevlar along with options of fleece or wool lining for extra comfort.

If you’re stick welding at high heats, you’ll need more heavy duty gloves that will withstand high temperature. If you’re MIG welding you can use medium-range gloves, and if you’re TIG welding you’ll be best with thinner leather to allow for maximum dexterity. See our guide on the best welding gloves.

Welding Footwear

Wearing high top boots or leather shoes will give you a good level of protection for your feet. Make sure that your footwear is made of leather or rubber. Keep the legs of your pants over the top of your boots for the best safety. Steel toe capped boots are the safest choice to protect your toes, and if you like lace-up boots then make sure you get a pair with a metatarsal guard. See our guide on the best welding work boots.

Shirt and Pants

Short-sleeved shirts and shorts are a big no when welding because you need to keep your skin shielded from the arc at all times. Any clothes that you are wearing must also be flame resistant. Denim pants are an acceptable choice, and you should also wear a welding jacket or apron. You can easily find cheap flame resistant jackets that are lightweight and do not restrict your movement. See our guide on the best welding jackets.

Welding Helmets

Simply having as much as a moments exposure to arc radiation can seriously damage your eye. It’s absolutely crucial that you wear professional and effective eye protection when you are performing a weld or are in proximity to a welding arc. Welding helmets come in two different types: fixed shade and auto-darkening, and we’ve explained about these below. See our favorite auto-darkening helmets.

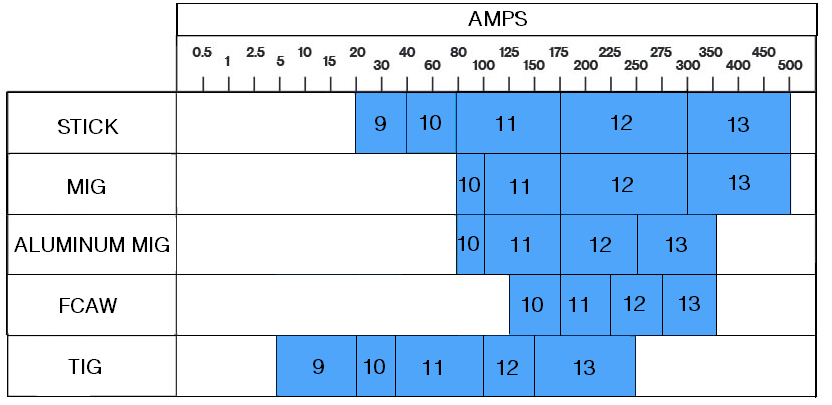

If you’re buying a fixed shade helmet, you’ll need to ensure that you choose the correct shade for the weld you are performing. This because they will only offer the same level of protection regardless of the level of light emitted from the arc. There are different grades of fixed shade helmet which are best suited to different amperage. Most helmets go from #9 to #13, with some ranging from #8 to #13. Look at the chart below to see which type is best suited for your welding application. For more information on this see the OSHA website.

Our favorite type of welding helmets are auto-darkening helmets which react to the arc and vary their shade depending on your type of weld. If you’re only performing one type of welding on one material with the same parameters, then fixed shade is a good choice, but if you’re going to vary your welding parameters then auto-darkening helmets are a must! Technology has greatly advanced in these helmets, they used to contain optical sensors which detected light from the weld and changed accordingly, but now they contain 2-4 magnetic sensors which pick up the magnetic field created by the arc. This means that auto-darkening helmets can now adjust the shade of the lens more reliably, and much quicker. You can now buy an auto-darkening helmet that will adjust in as little as 0.00003 seconds.

If you buy an auto-darkening helmet, you must make sure it adheres to the official ANSI Z87 safety standards so you know it’s properly tested and safe to wear.

Bandanas

You should also have a layer of protection between your head and your welding helmet. For this, we recommend either a bandana or a thin cotton hat to ensure your head has the best possible protection.

Safety Glasses

Safety glasses should be worn underneath your welding helmet to further protect your eyes, or on their own if you’re cutting or only need to protect them from dust or debris . These should ideally cover your eyes at the side with either wraparound lenses or side shields and should meet ANSI Z87 standards. You can also wear safety glasses instead of a welding helmet if you need to get into tight areas, however, this means you’re not protecting the rest of your face. Check out our guide to the best welding safety glasses.

Welding Respirator

A welding respirator is a great piece of safety gear that can greatly reduce your exposure to harmful welding fumes. They can either fit under your welding helmet or you can get a welding helmet with a built in respirator system.

Welding Hazards

Gas Cylinders

Gas cylinders can be very dangerous. If you knock one over and the valve pops off, it’s going to shoot across the room. If it hits you then you’re in serious trouble. Make sure your cylinder is securely chained to a well secured, stationary and upright cart or support at all times. If you’re moving the cylinder attach a protective cap to the valve to prevent it from sustaining any damage. Most importantly, read all the safety guidelines from your gas cylinder provider before using your cylinder.

Fume Exposure and Ventilation

The fumes that are emitted when you’re welding can cause a health hazard both to yourself and any others in the area. This is especially important if you’re welding in a confined space where fumes can accumulate. If you’re using a shielding gas, the last thing you want is Carbon Dioxide or Argon to be getting released into the room. There’s also other dangerous fumes emitted that you may not have heard of, such as Hexavalent Chromium, which is produced during welding and cutting stainless steel and some other alloys.

If you want to see how big a thing this has become then just search online for “welding fume lawsuit“. There’s a huge number of cases where companies have been sued for causing respiratory problems, and more lawyers looking to find welders to represent.

When you’re welding, check to see if there’s an exhaust hood in the area you’re welding so that clean air can get into the area. If there isn’t one available then play it safe by either moving the work piece or getting one installed. There are other options you can go for such as downdraft tables and bench top fume extractors, which are a good choice for small operations. If you’re an employer, you’ll need to comply with OSHA’s regulations, so it’s worth the investment.

Clutter and Physical Injuries

Try to keep the area you’re working in free from clutter. It can be tempted to leave spare bits of metal and tools lying around, but it’s worth it to spent that extra few seconds moving stuff out the way. There’s nothing worse than tripping over something and injuring yourself, and without clutter you’ll increase your welding speed as the tools you need will be easier to locate. Also, try to group or hide your cables so that they don’t get tangled and you don’t trip over them

Fire Hazards

Remove any fire hazards such as paper documents, towels or clothes that might be lying around. Welding sparks can fly when welding so ensure any flammable items are removed from the work space. Ensure you have a fire extinguisher, fire alarm and emergency exit just in case!

Water Hazards

It might sound obvious, but make sure you’re welding in a dry area without water. Water conducts electricity so don’t weld in wet or rainy areas. Even if there’s just a bit of water on the ground, get it cleaned up. Water can kill you!

You make a great point that it’s absolutely crucial to wear professional and effective eye protection when you are performing a weld. My brother is working on a big project, and he needs to get some welding done. However, he doesn’t own a welding helmet, and since he doesn’t know too much about welding it’s probably a good idea if he just hired a professional to help him get the project finished.

Hi Monica, yes you’re right, it’s crucial! There’s definitely an argument for hiring a pro to finish the project – but that takes away some of the fun! A welding helmet is expensive but will serve you well over time, or if you’re not looking to spent too much, you can always protect your eyes with some welding glasses.

I’d like to thank you for your explanation about the safety guide for welding. In my opinion, I believe that a well-dressed welder is a must. But above all things, he should be well trained and certified before he does his tasks.

Thanks for pointing out that keeping your surrounding dry is a must since water conducts electricity, and it can kill you if this happens. I will share this information with my best friend who told me that he might pursue this career once we finish high school. He is already starting to look for courses and schools that will offer the best training for him. It will ensure that he will be safe in the future.