Spot welding, or resistance spot welding, is a welding process used to weld sheet metal by applying heat and pressure with an electric current through a copper alloy electrode.

There are different types of spot welders, spot welders for 18650 batteries are different to hand held squeeze-type spot welders. Squeeze-type spot welders have large metal electrode jaws which go either side of the metal sheets, creating heat and pressure in a small spot to weld them together. Battery spot welders have electrodes on the same side and are typically used for connecting 18650 batteries.

Contents

Best Hand Held Spot Welders

1. Stark Professional Portable Spot Welder

![]() Best portable hand held spot welder

Best portable hand held spot welder

|

|

Our top pick is the Stark hand held spot welder. This welder is designed to be portable and create strong spot welds at speed. The handle on the top lets you easily carry it and the single phase design lets you add the sheet metal and simply press the lever and have a completed weld in seconds. It is available with either 120V and 220V capability. To use the 220V you will need to have a 220V power outlet. If you only have your standard household power supply you will need the 120V. The price is very similar so we prefer the 220V model if you have the capability because it has that bit extra power.

The 120V unit has 13.5 Amps electrical current, weights 27 lb and can weld up to 1/8″ combined sheet metal (1.5mm + 1.5mm). This is ideal for home hobby welders on light duty projects. The duty cycle is 50% @ 1.5kVA which is fine.

The 240V unit has 16 Amps electrical current, weighs 27.5 lb and can weld up to 3/16″ combined thickness. This is perfect if you’re want a bit more power and have a proper workshop with 220V capacity. The duty cycle is 50% @ 2.5kVA.

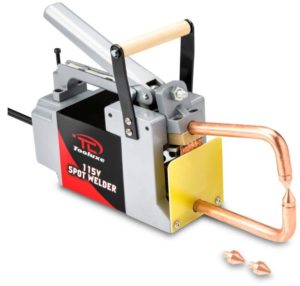

2. Tooluxe RIDGE10915L 115V Spot Welder

|

|

The RIDE10915L is another compact, hand held spot welder. It has a handle on top which helps with portability, however at 34 lb it can be quite difficult to carry. It’s very simply to use, all you have to do is apply pressure on the sheet metal and press the lever and you can have instant spot welds. It runs off 115V power and has 6.6kw input capacity with duty cycle 30% @ 6.6kw. It welds up to a thickness in 12 ga combined (1.0mm + 1.0mm) and has a 7″ throat depth. It also comes with a spare pair of welding tips for when you need to replace them. It’s heavier and less powerful than the 120V Stark unit, but still performs good welds so is worth considering depending on the price.

Best Battery Spot Welder

1. SUNKKO 709A Battery Spot Welder

![]() Best battery spot welder for 18650

Best battery spot welder for 18650

|

|

The 709A is a spot welder purpose build for battery welding 18650, 14500 and other lithium batteries. It can weld 0.2mm max thickness for pure Nickel and 0.35mm max thickness for Nickel coated steel. This model is available at a reasonable price because it’s a basic unit, but it does the job. It includes a foot pedal to help improve your precision and features. It also has 2~18 welding pulse selection and 1~8 welding current adjustment so you can adapt your performance when welding thicker nickel strips. Overall it’s an affordable and basic spot welder that will have no trouble welding your batteries.

How does a squeeze type spot welder work

A handheld squeeze type spot welder is easy to use, there are just a few basic steps you’ll need to go through.

- Start by lining up the pieces of sheet metal into the position you want them welded together. You’ll be best clamping the metal in place so that it doesn’t change position. Make sure the metal is clean and there’s no grease, paint or oxides on the surface.

- Next you should make sure the electrodes are directly in line with each other when they are pressed together.

- With the electrodes in position and the sheet metal secure, use the button or pedal to generate a current through the copper alloy electrodes and pressure is applied to the weld area by squeezing the electrodes together. This generates heat which melts the metal and fuses it together to form the weld joint.

- When the metal sheets have been joined together accurately, release the electrodes and reposition them in the next spot you want to weld and repeat the previous steps until you have completed all your spot welds.

How does a battery spot welder work

If you’re looking to weld lots of 18650 Li-ion batteries together for a project you’re working on, you’re best using a spot welder. If you solder the cells you can easily end up ruining them. The main differences with a battery spot welder compared to a squeeze-type is that the electrodes both touch the same side of the metal sheet and it will typically weld much thinner metal.

Benefits of a spot welder

Increased productivity

If you’re doing a lot of sheet metal work in your workshop, you’ll probably get a bit tired of making plug welds. You’ll be drilling holes, aligning the parts, welding and then finishing the weld. At some point you’ll start wondering if you should invest in a spot welder.

Spot welders are a really great tool if you want to quickly weld sheet metal, you can literally complete the weld within seconds. All you need is flat, thin and clean metal sheets, the spot welder and electricity and you can fly through completing welds.

Small heat affected area

One of the benefits of spot welding is that the heat affected area remains very small because energy can be delivered to the spot in under 1 second. If you’re welding autobody, you’ll want the heat affected zone to be as small as possible in order that the steel’s structural integrity is not compromised. Spot welders produce heat very efficiently so weld times are decreased and the heat affected zone is greatly reduced compared to MIG or TIG welding. This is why spot welding is used extensively in car manufacturing and autobody repair.

No consumables

Spot welding is convenient and low-cost because you don’t use any consumables such as filler metal or welding gas. Spot welding only requires heat generated by an electric current and pressure, so as long as you have a power source you’re good to go.

How to prevent spatter and electrode sticking

If your electrode is sticking or you’re getting spatter, there’s a number of possible causes.

- Electrode misalignment: Ensure the electrodes tips are perfectly aligned when you squeeze them together. Tips should be square to the metal sheet when they touch it.

- Contaminated work surface: Electrode sticking can occur when the surface of the metal contains oxides, grease, paint or dirt. Ensure the metal is clean.

- Contaminated electrode tip: Electrodes can become contaminated when welding galvanised steel. Clean your electrode tip before spot welding to prevent electrode sticking.

- Poor conditions: If your welding current is too high or you hold the weld longer than is recommended, this can cause weld splash. Always follow the correct parameters.

Which metals can you spot weld

Steel is the best metal to spot weld because it has low thermal conductivity and high electrical resistance, including stainless, mild and galvanized. Galvanised steel requires a higher current and the electrode tip will need to be changed or dressed because it can become contaminated. Nickel alloys and titanium can also be spot welded. Spot welding is not suitable for aluminum or copper alloys such as bronze.

Spot Welder Safety

Spot welding is safer than other types of welding that use an arc and generate more heat such as MIG, TIG and Stick welding because there are no UV rays which can damage your skin and eyes if left uncovered. However, spot welding can produce sparks so you must follow all the instructions in the manual and take care. Typically, you should wear safety glasses, a leather apron, welding gloves, a face shield and welding sleeves. Handheld spot welders can also be pretty heavy so you need to be careful that you drop it on your foot.

What to look for in a spot welder

Metal thickness

The key thing when buying a spot welder is understanding the thickness of sheet metal you want to weld. Spot welders are best suited for thin sheet metal. Squeeze type spot welding would typically be able to weld sheets from 0.5 to 3mm (0.020 to 0.118 in) thickness. With hand held models handling up to 2 sheets of 16ga. Battery spot welders typically weld from 0.03 to 0.2mm.

Price

Spot welders are a very cost effective tool if used frequently, you don’t need consumables and you can save a lot of welding time. For battery spot welders, the price can be off putting if you only want to weld one set of 18650s because the price isn’t that much different from buying a new battery. However, if you think you might build more batteries then it’s worth the investment.

Voltage

Spot welders can be either 220v or 110v. 220v units are more powerful, but you need a 220v power outlet in your workshop. If you only have standard household 110v power supplies then you will need a 110v model.