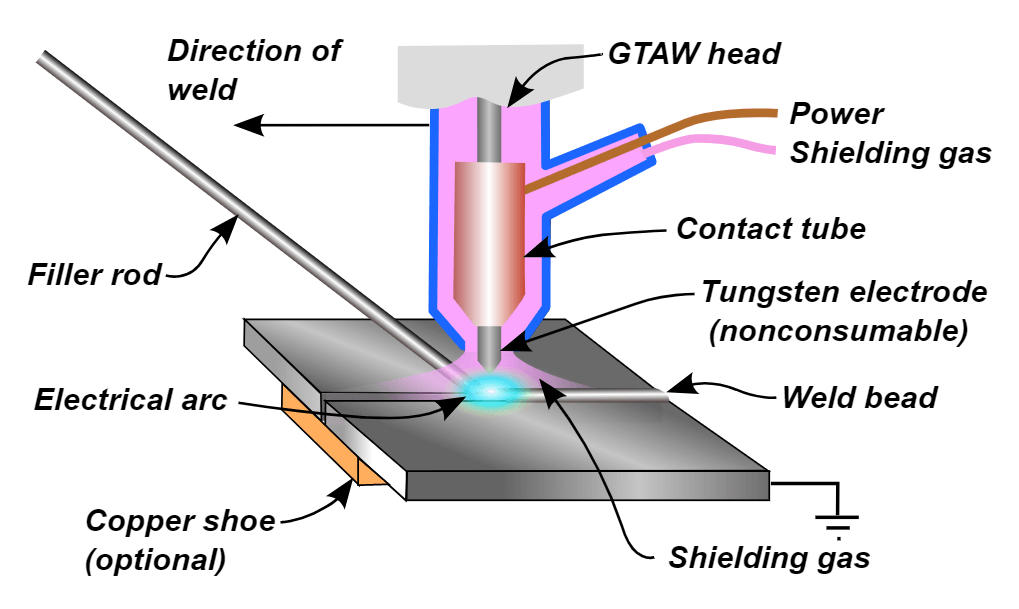

TIG Welding or Gas Tungsten Arc Welding (GTAW) is a commonly used welding process that is used when high quality, clean and precise welds are required.

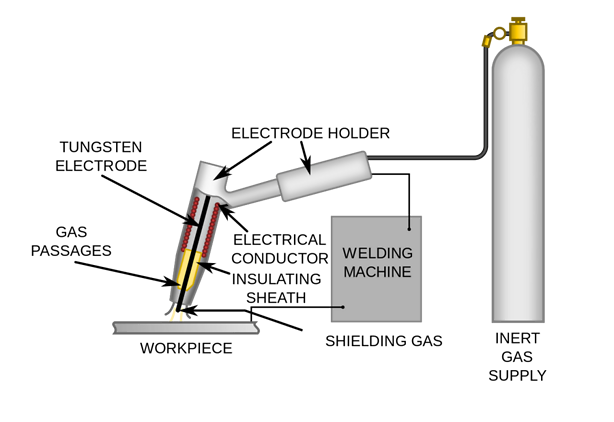

TIG welding happens when an arc is created between a non-consumable tungsten electrode and the workpiece metal. Shielding gas is fed through the torch which surrounds the tungsten electrode and protects it from contamination.

The welder presses a foot pedal to control the amperage. The filler metal is a wire that is dipped into the weld pool by hand to fill the joint. There is no excess spatter because you only feed in the filler metal that is required and there is no flux.

Pros of TIG welding:

- High weld quality and precise welds, you get a much greater level of control.

- Less spatter

- Low distortion

Cons of TIG welding:

- High operating costs

- More dexterity required

- Slow welding speed because the filler deposition rate is low

Contents

TIG Welding Setup

See below how to get set up ready for TIG welding.

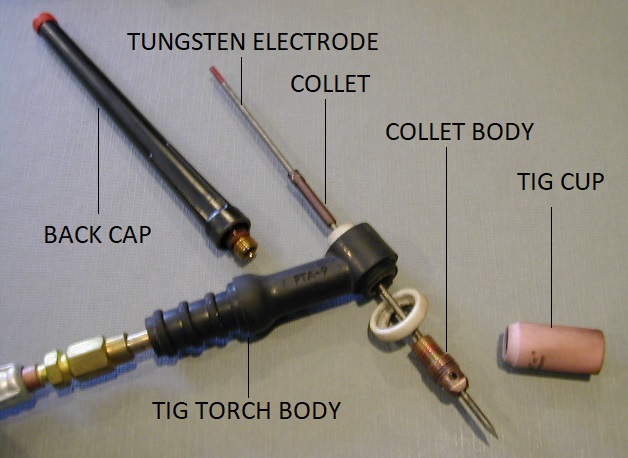

TIG Torch Setup

To start with you need to get your torch set up. A TIG torch body needs four main components and a tungsten electrode for set-up. The torch body holds the collet, collet body, back cap, and cup. These components are what hold the electrode in place and help distribute the shielding gas. A TIG torch requires the collet and collet body to match the size of the tungsten electrode that is used.

Collet Body

The collet body screws into the TIG gun to hold the electrode in place and distribute shielding gas. The collet will slide into the back and the gas cup will be added on the front.

Collet

The collet holds the tungsten electrode and connects it to the TIG torch. The Collet needs to be the same size as the tungsten electrode to ensure that it smoothly transfers the current from the torch into the electrode.

TIG Cup

The TIG cup dictates how much shielding gas is distributed to the weld pool. The cup size is chosen based on the size of the joint that will be welded. The diameter of the cup will also affect the angle at which you can hold the torch. TIG cups have a number assigned to each size diameter.

Size 4: 4/16 inside diameter

Size 5: 5/16 inside diameter

Size 6: 6/16 inside diameter

Size 7: 7/16 inside diameter

Tungsten Electrode

The tungsten electrode is not consumed during welding, it channels the amperage and creates the arc. It is held in the gun with the collet which is screwed into the gun.

There are different coloured bands on the electrode depending on what you are welding. The most common coloured electrode for steel DC TIG welding is red 2% thoriated but it’s not suitable for aluminum. For AC aluminum there’s green which is pure tungsten. Purple is OK for steel and aluminum.

Before creating the arc you should grind the tungsten tig to a point so you can get a tight arc. If the tungsten tig touches the work metal it will ruin the tip and you will need to grind it again before continuing to weld. You want the tip of the electrode to be very close to the workpiece but not to touch it.

Electrodes come in different diameters: 1/16”, 3/32” and 1/8″. The diameter of this will need to match the filler rod diameter.

The electrode and filler rod diameter will depend on how much filler metal you want to me deposited into the weld pool.

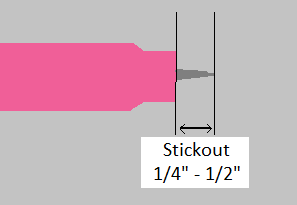

Electrode Stickout

When you insert the electrode into the TIG torch you will need to measure how much the electrode sticks out from the bottom of the torch.

The stickout is measured as the distance from the front of the cup to the tip of the electrode.

The stickout is usually between ¼ and ½ inch. The stickout should be at most 1.5 times the diameter of the cup. A shorter stickout will probably be easier for beginners. If the stickout is too long then you won’t be able to angle the electrode into the weld properly and won’t get enough penetration.

Filler rod

With one hand holding the torch, the filler rod is held in your other hand and is manually added to the joint a bit at a time. This gives you full control over the amount of filler metal that is deposited.

You should angle your filler rod at around 15° angle from the work metal from the horizontal. Carefully but quickly dip the filler into the weld pool to deposit filler metal.

There are lots of filler rods to choose from, you’ll need to match the filler rod to the metal you’re using. There are different ones for mild steel, stainless steel and aluminum.

The most common filler rod diameters are 3/32” and 1/16”, the thinner ones are better if you’re welding in a tight area and thicker ones are better if you want to deposit more filler metal. The filler rod diameter will need to match your electrode diameter.

TIG welder

Your power source will be a TIG welder. The TIG torch, TIG pedal, and welding clamp will be connected to it.

DC TIG welding steel, use DC electrode negative. When welding aluminum, use AC. For full instructions on how to use your TIG welder and settings refer to your TIG machine’s operating manual. Read more about TIG welders.

Foot Pedal

The foot pedal connects to the welding machine and regulates the heat. The more you push down on the pedal the more heat you get. Practice controlling the heat before you jump straight into welding your workpiece. Keep the heat consistent so the weld doesn’t shrink or expand across the joint.

Shielding Gas

The shielding gas will flow through the TIG torch to protect against contamination. Usually when TIG welding you’ll use 100% argon so you won’t be able to use your MIG gas.

Argon/Helium mixture can also be used to help increase heat input and Argon/Hydrogen mixture can also be used but it may result in hydrogen cracking.

Workpiece

Clean the workpiece so it is free of any paint, dirt, grease, oil, zinc or any other coating. You need the joint to be free of any impurities and perform the weld onto clean shining metal.

Performing the TIG weld.

When you’ve got all your equipment set up then you’re ready to start TIG welding. To start the arc you’ll need to scratch the tungsten, then you can add filler wire into the joint.

Torch movement

This guide helps to walk through the torch movement and position. Typically you’ll look to have the torch learning towards the direction of the weld at an angle of 10-20 degrees from the vertical. The tilt helps the weld pool to form just in front of the torch making it easier to add the filler metal.

TIG welding speed

TIG welding is much slower than MIG or stick welding. However, it might seem quicker when you start out as there’s a lot of different things to focus on!

The torch travel speed is about 1mm/second, stopping to add the filler metal. If you can find a position where you can rest your hand on the table it will make it a lot steadier.

Check out this video on “walking to cup” for a cool TIG welding technique.

Feeding the TIG Filler Rods

Before you jump straight into TIG welding, have a practice at feeding the filler wire through your fingers. The wire can be fed however you like as long as it feels comfortable and your fingers a safe distance from the arc.

Hold the filler wire high up to stop your hand getting burnt by the arc. You’ll need to keep feeding it into the weld pool as it gets shorter. They are easier to handle if they’re cut in half.

Safety

TIG welding doesn’t create sparks and spatter like MIG and stick welding, but the arc still creates dangerous UV light so you need to cover your body to protect yourself. An auto darkening helmet, welding jacket and gloves are must haves.

TIG gloves will typically need to allow for greater dexterity so you can effectively feed the filler rod. Make sure to read all of your equipment’s safety guidelines before welding and don’t use this advice as a substitute for anything written in your operating manuals.