Spot welding came into use in the period 1900-1905. It is now the most widely used of resistance welding processes. Spot welding is employed for joining sheet to sheet, sheets to rolled sections or extrusions, wire to wire, etc. Spot welding is used for joining relatively light gauge parts (up to about 3 mm thick) superimposed on one another as a lap joint.

What is Spot Welding?

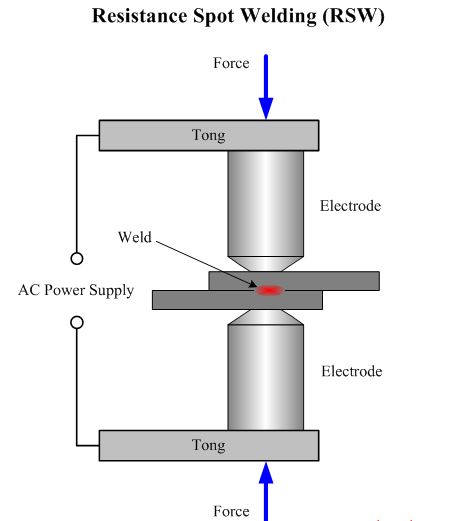

Spot welding is a resistance welding process in which overlapping sheets are joined by local fusion at one or more spots by the heat generated, by resistance to the flow of electric current through workpieces that are held together under force by two electrodes, one above and the other below the two overlapping sheets

Image of a handheld spot welder welding two pieces of metal together

Advantages of Spot Welding

- Low cost

- No filler metal needed

- High speed of welding

- Dependability

- Less skilled welder can operate

- More general elimination of warping or distortion of parts

- High uniformity of products

- Operation may be made automatic or semiautomatic, and

- No edge preparation is needed

How Spot Welding Works

Before spot welding you must make sure that:

- The base metal is clean; i.e. free from grease, dirt, paint, scale, oxide etc.

- The electrode tip surface is clean, since it has to conduct the current into the work with as little loss as possible. Very fine emery cloth may be used for routine cleaning.

Once that is done, the welding operator can use the following steps:

Step 1. Electrodes are brought together against the overlapping work pieces and pressure applied so that the surfaces of the two workpieces under the electrodes come in physical contact

Step 2. Welding current is switched on for a definite period of time. The current may be of the order of 3000 to 100,000 A for a fraction of second to a few seconds depending upon the nature of material and its thickness.

As the current passes through one electrode and the workpieces to the other electrode, a small area where the workpieces are in contact is heated. The temperature of this weld zone is approximately 815°C to 930°C.

To achieve a satisfactory spot weld, the nugget of coalesced metal should form with no melting of the material between the faying surfaces.

Step 3. At this stage, the welding current is cut off. Extra electrode force is then applied or the original force is prolonged. This electrode force or pressure forges the weld and holds it together while the metal cools down and gains strength.

Step 4. The electrode pressure is released to remove the spot welded workpieces

Spot Welding Two Different Workpieces

In order to obtain a proper spot weld between two workpieces, the fusion zones in the two pieces should experience the same degree of heat and electrode force.

The problem arises when two different thicknesses of the same material or same or different thicknesses of two different materials having different thermal and electrical conductivities are to be spot welded.

Unequal thicknesses and many thickness combinations can be successfully spot welded; but in general, with the introduction of more than two pieces, the effects contact resistance, heat loss, and heat transfer are encountered. Proper heat balance may be achieved by using the following techniques.

When welding two different thicknesses of the same material, e.g. mild steel, use a smaller (electrode) tip area on the side of bigger thickness. This will increase current density on the side of bigger thickness and thus help in obtaining equal degrees of fusion in the two pieces to be welded.

When welding two dissimilar metal sheets of varying conductivity, e.g. those of a high copper content alloy and stainless steel, use a smaller (electrode) tip area on the side of the high conductivity alloy. This helps obtain equal degrees of fusion by varying current density.

Spot Weldable Metals

Low carbon steels (mild steel) are best suited to spot welding. Ferritic stainless steels behave very much as mild steel, however, the pressure should be kept a little longer after welding.

Austenitic (non-stabilized) stainless steel requires heating and eventual cooling to take place in the shortest possible time. High capacity spot welding machines are preferred for welding such steels.

In coated steels, paint should be removed from the place of spot welding as it is non-conductor of electricity. When tin, zinc (galvanized) and lead coated steel sheets are spot welded, there is a loss of protection of the weld as a result of melting and vaporization of these low melting point coated metals.

Aluminum and Aluminum Magnesium alloys may be spot welded, but require higher levels of current due to their low resistance. The oxide film on them must be removed.

For welding copper up to 1.5 mm thick, hardfaced or pure tungsten (welding) electrodes are necessary. For bigger thicknesses spot welding is not preferred.

Copper and aluminum and their alloys are very good conductors of heat and electricity which makes them difficult metals to spot weld compared to mild steel.

Nickel, Nickel alloys and Monel Metal require machine capacity and settings rather similar to those employed for spot welding stainless steels.

Applications of Spot Welding

- Spot welding is a commonly used application in automobile and aircraft industries.

- Spot welding of two 12.5 mm thick steel plates has been done satisfactorily as a replacement for riveting.

- Many assemblies of two or more sheet metal stampings that do not require gas tight or liquid tight joints can be more economically joined by spot welding than by mechanical methods.

- Containers such as receptacles and tote boxes frequently are spot welded.

- The attachment of braces, brackets, pads or clips to formed sheet metal parts such as cases, covers, bases or trays is another application of spot welding.